Metal stamping tools

SIVA produces all the tools used for production in its own Tooling department.

The experience gained over decades of hard work in solving problems linked to stamping in the Shearing Department has led us to improve the design and construction techniques continuously, owing to the constant flow of innovative ideas from our qualified engineering staff.

Our tools are especially suitable for applications requiring the highest levels of precision and productivity: they stand out for the high stamping speed, quick set-up times and ease of maintenance; they are designed to afford the utmost production flexibility.

Maximum tool size: 1,000 x 600 mm.

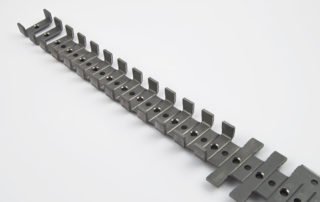

Types of tools manufactured:

Progressive tools, used for the majority of stampings produced; progressive tool stamping is a forming process that uses a series of stamping stations to perform simultaneous operations on sheet metal.

Compound tools, used for the production of highly critical parts or with special dimensional requirements.

Transfer tools, used to produce details with specific technical or aesthetic requirements (e.g. deep drawn edges with a consistent thickness), optimise the consumption of raw materials, and in general to create pieces that would usually require different processing phases in a single operation.

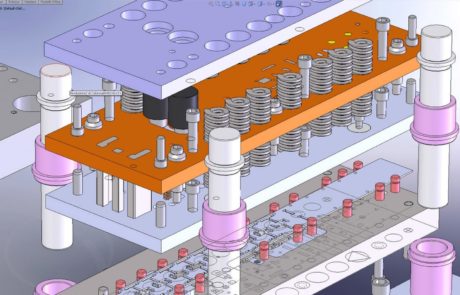

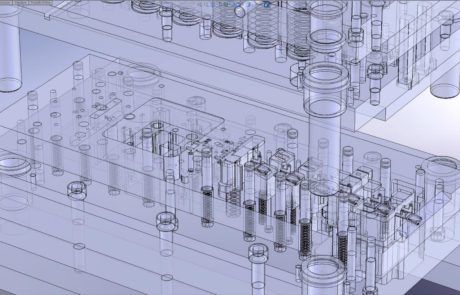

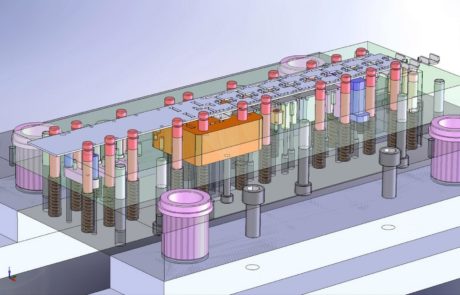

Designing

SIVA produces all the tools used for production in its own Tooling department.

Starting with a drawing or a sample, our engineering staff design the tool in conjunction with the customer, with whom they devise the best solution to produce stampings in the most cost-effective and productive way.

During the designing phase, the staff also assess solutions to facilitate maintenance operations on the tool, which may entail inserts in the matrix, separate sections, etc.

All the tools are designed using 3D CAD software, which is kept constantly up-to-date.

Tool construction

The range of products includes small and medium-sized tools for shearing sheet metal and for deep drawing of small parts, equipped also with tapping machines for the production of threaded parts directly from the tool.

To ensure the tools have an extended useful life, low maintenance costs and consistently respect of all stamping tolerance values, they are built using appropriate materials for the performance levels required: C45, X200CrW13 (K107), X160CrMoV12 (K110), X210CrMoV7,5 (Vanadis 6), X50CrMoV5,3 (Unimax). Matrix tools and punches can be coated with PVD-CVD for frequently used tools.

Tooling

Over the years, SIVA has kept the machinery in its Tooling department constantly up-to-date.